Dorsal 100/200

This is a modular solution supporting MiR 100 and MiR 200 robots. The module's built-in drive enables docking to the material transport platform. The universal system allows for transporting various materials on a standard platform.

Dorsal 100/200 enables flexible operation with maximum utilization of MiR robots' potential in the facility.

By installing the module on the MiR robot, it becomes possible to increase the payload capacity of MiR100 vehicles to 250 kg and MiR200 vehicles to 350 kg using a standard platform. Additionally, Dorsal guarantees space savings, as it eliminates the need for docking stations, allowing the platforms to stand anywhere in the facility. With its pick-up-and-go feature and the absence of the need for docking stations, Dorsal ensures full customization of transport operations to meet the company's needs, and its compact design perfectly complements the size of the MiR robot.

What you’ll gain:

Transport platforms tailored to process needs

Ease of use, simple programming

Flexible robot operation

Maximization of MiR robot potential

Pick-up-and-go, no docking stations

Compact design

Dimensions (length X width X height)

805 x 445 x 70 mm

Protection

IP40

Additional Equipment

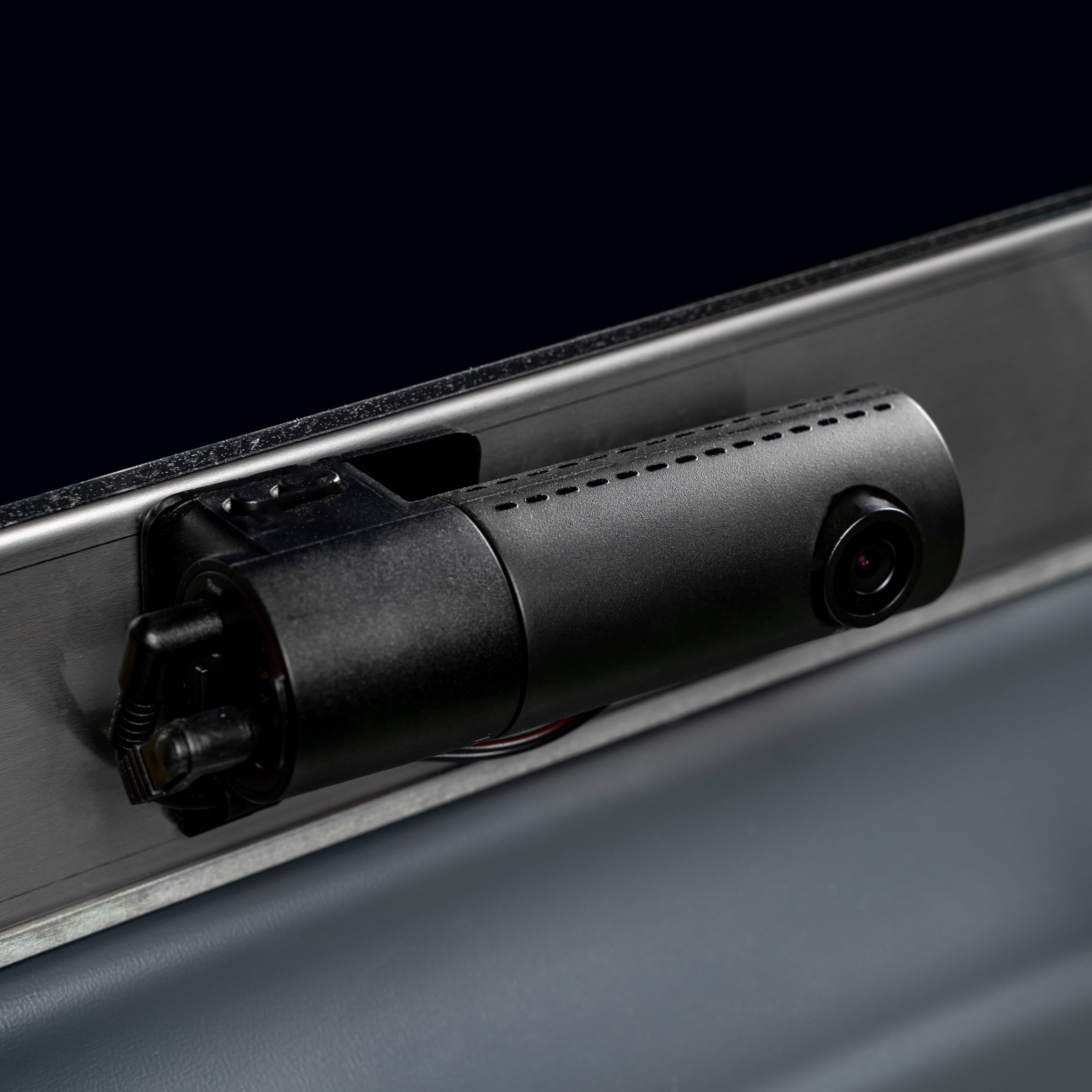

Spot Light Kit, Dashboard Camera Kit, QR code scaner, RFID reader

Communication

Modbus TCP

Operating height

440 mm

Power supply

24VDC

Payload

MiR 100 do 250 k a MiR 250 do 350 kg

Additional equipment:

CASE STUDY

Whirlpool Corporation

Automated transport of semi-finished products from the preparation area to the production line.

3 MiR robots with Dorsal docking modules ensure smooth delivery of components, aiming to increase the efficiency of the production line by delivering parts at the right frequency.

Products:Dorsal 100/200Dashboard camera kit